Chain Magnetic Separator

Chain Magnetic Separator are used for the cleaning of liquids contaminated with magnetizable solid particles and foreign oils. F.E.S. separator systems can be used in full-flow or bypass cleaning applications. The separation performance varies depending on the level of contamination and the volume flow rate.

Note: The separator systems can be supplied via a separate supply pump, existing system pumps (with sufficient reserve capacity within the existing system components), or a free inlet (with sufficient geodetic height difference).

Advantages:

- No filter aids required

- High separation efficiency

- Large throughput capacity

- Large active separation surface due to favorable separation geometry and optimal arrangement of magnets

- Low wear and tear

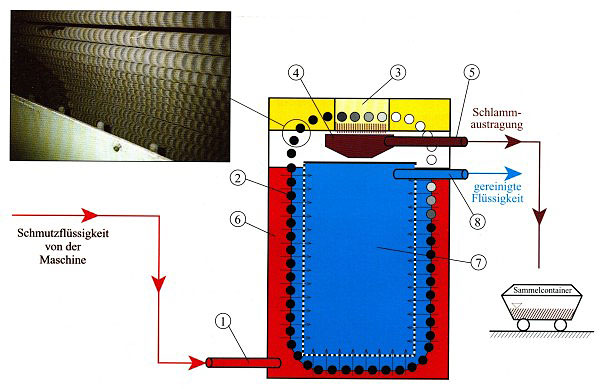

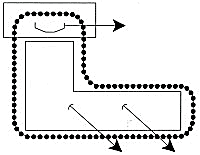

Operating Principle: The contaminated liquid is supplied to the separator through the flange (1) located at the bottom. An internal distribution system ensures optimal flow conditions in the dirt container (6) before the liquid encounters the continuously running magnetic rods (2) within the container. The flow velocity of the fluid is reduced to a minimum in the vicinity of the magnetic rods due to special container internals. The favorable flow conditions, combined with the extremely strong magnetic force of the F.E.S. magnetic rods, retain up to 100% of the magnetizable contaminants, forming fine “filter cakes” on the magnetic rods. These filter cakes overlap significantly due to the small distance between the magnetic rods, creating a continuous “filter layer.”

This developing filter layer is capable of capturing non-magnetizable particles and even foreign oils, transporting them to the discharge area (3) of the separator system. In the discharge area, the layer adhering to the magnetic rods is scraped off and transported to the discharge opening (5) via an integrated conveying system (4). The liquid flowing past the magnetic rods enters the clean area (7) of the separator system and is discharged into a clean container through the overflow outlet flange (8).

Equipment: The standard equipment of a magnetic rod separator includes:

- Dirt container

- Separate clean container

- Flow-optimized container internals

- Continuously circulating magnetic rod chain, equipped with F.E.S. stainless steel magnetic rods known for their excellent fluid compatibility and high magnetic force

- Discharge device

- Conveying system for the separated sludge

- Inlet flange, outlet flange, and connection fitting for the discharge hose

On request, collection containers for the separated sludge are available.

Application: Magnetic rod separators have primarily been used in the rolling mill industry. However, they are increasingly finding applications in machining operations, especially to relieve filter components in central systems and for challenging filtration tasks.

Available Sizes: The entire range of 40 to 350 active magnetic rods is possible. Each system is tailored and designed to meet the specific requirements and preferences of the future operators.

The volume flow rate ranges from 500 to 8,000 l/min for standard configurations, depending on the application and the number of active magnetic rods. Special designs can accommodate lower volume flow rates.

Magnetic rod separators have so far been used preferably in the rolling mill sector. However, they are increasingly being used in machining operations – here, especially to relieve the filter components within central systems, to reduce the consumption of filter aid materials such as fleece, and especially for challenging filtration tasks.

Available sizes:

The entire range from 40 to 702 active magnetic rods is possible. Each system is tailored and designed for the specific problem and the wishes of the future operators.

The volume flow rate varies depending on the application and the number of active magnetic rods between 500 and 15,000 l/min for the standard versions.

However, special designs also allow for lower volume flows.

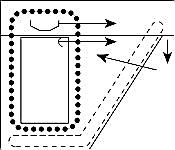

Available design variants (standard) of the F.E.S. magnetic rod separators:

| Container version

| ||||

Container version with bottom scraper

| |||||

Straight frame version

| |||||

| Angled frame version

|

Our Service

Each filter system is specifically designed and customized for the specific application. We utilize our experience, in-house laboratory tests, as well as portable pilot plants for on-site testing at your company.