Plate Precoat Filter

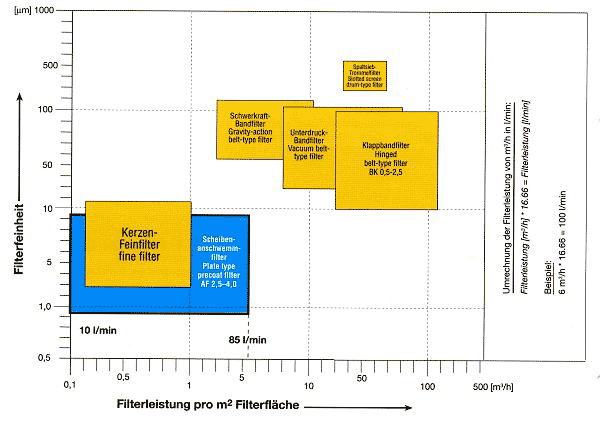

Plate Precoat Filter are used for the fine filtration of low-viscosity oils. This cost-effective filter is a compact device designed to supply individual machines. The achievable filtration fineness is between 1 and 5 µm in NAS 3-7. The filter regeneration and cleaning of the filter discs are done manually.

Advantages:

- Small footprint

- Excellent filtration results

- Low installation effort

- The filter geometry can be customized to match the machining machine (on request)

- Affordable price

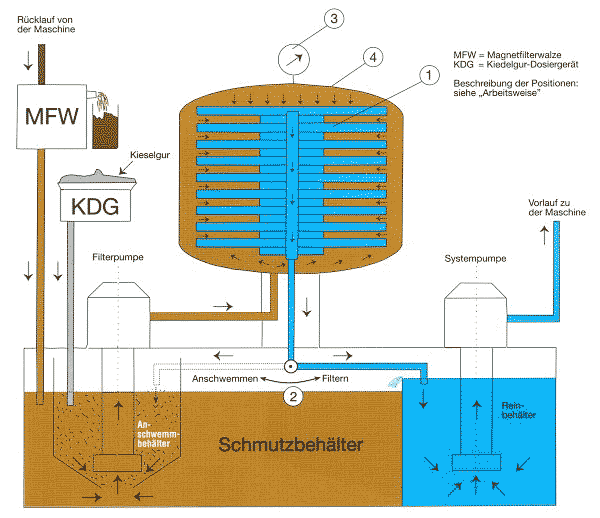

Operating Principle:

Swelling: The entire tank is filled with oil. Before filtration can begin, the filter discs (1) need to be swollen with a filter aid (diatomaceous earth, cellulose, perlite).

Filtration:

After the precoat, the operator manually switches to filtration and directs the filtrate into the clean tank (2). The system pump can now be switched on to supply the processing machine. The achievable filtration fineness is 1 – 5 µm, depending on the filter aid used.

Regeneration:

The filter contamination is indicated on the pressure gauge (3) of the filter dome (4). When the pressure exceeds approximately 1.1 bar, the filter needs to be cleaned after the end of the shift or during longer machine downtime. After draining the liquid from the filter container, a drying phase of several hours for the sludge should be observed. When running with redundant domes, there are no processing breaks

Equipment: The standard equipment of a disc-type swarf filter includes:

- Container divided into dirt and clean tanks with separate precoat tank

- Submersible pump for filter and machine supply

- Filter container (domes) with inserted filter discs that can be removed for cleaning

- Filter dome and filter fabric made of stainless steel

OPTIONAL ADDITIONAL DEVICES:

- Magnetic roller for pre-separation

- Filter aid dosing device

- Oil mist separator for oil mist extraction at the machining machine

- Compressor cooler or heat exchanger to keep the processing temperature constant

Available sizes:

- AF – 2.5 m²

- AF – 2 x 2.5 m²

- AF – 4 m²

- AF – 2 x 4 m²

- AF – 3 x 4 m²

- AF – 4 x 4 m²

The filtration capacity ranges from 1 to 85 l/min per m² of filter area, depending on the application.

The separation range is determined by the filter aid used and ranges between 1 and 5 µm. The viscosity of the cutting fluid and the amount of swarf significantly affect the filter’s service life. Long service life is achieved by generously dimensioning the filter area. For this filter variant, manual operation is preferred due to cost considerations. Partial automation, such as regeneration notification, automatic filter aid dosing, and switching to a spare filter, is possible. The electrical control is typically done from the main control cabinet of the machining machine.

Our Service

Each filter system is specifically designed and customized for the specific application. We utilize our experience, in-house laboratory tests, as well as portable pilot plants for on-site testing at your company.